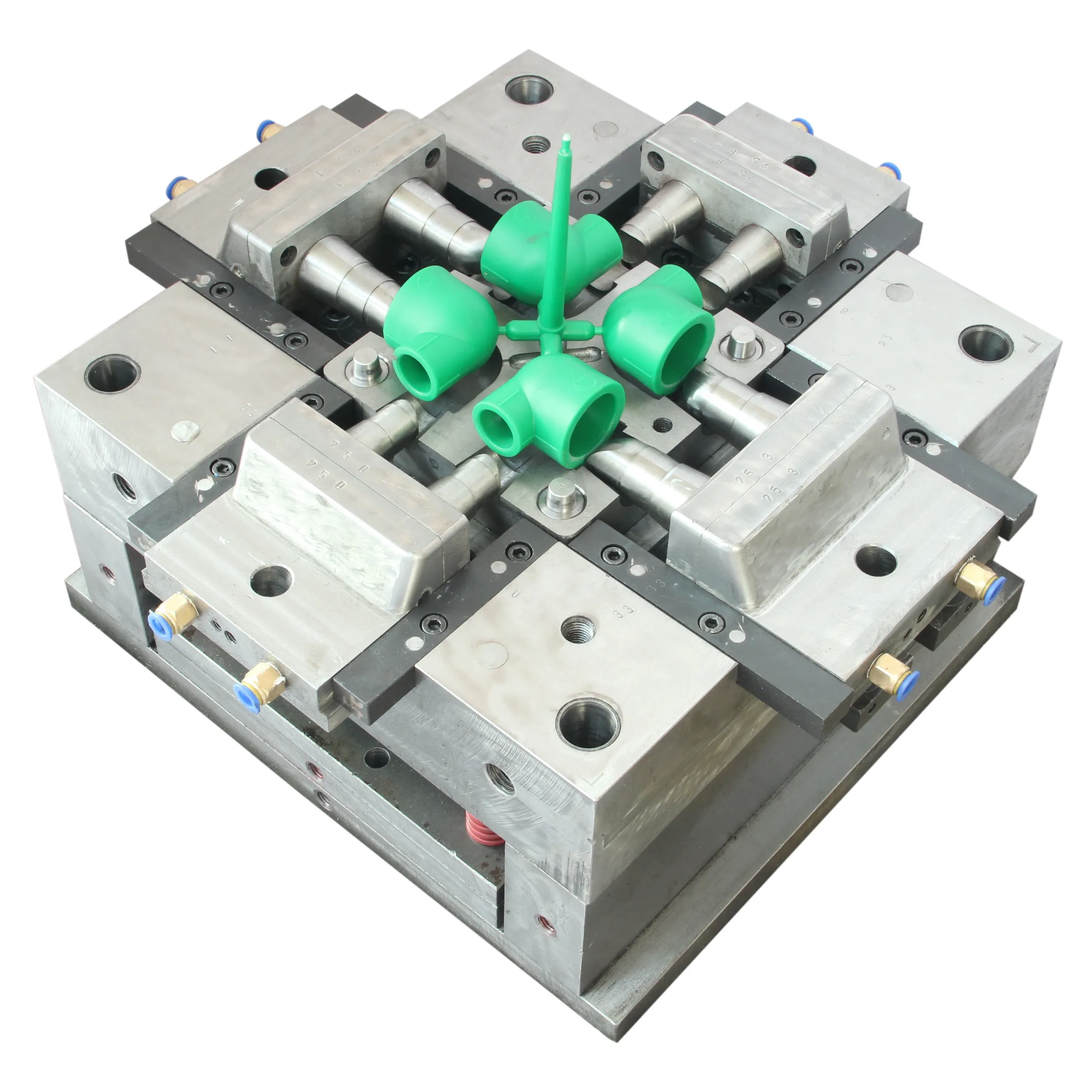

Pp-R90 Degree Mold

PP-R 90-Degree Elbow Mold: Design and Functionality A PP-R 90-degree elbow mold is a precision tool used in the injection molding process to manufacture polypropylene random copolymer (PP-R) pipe fittings, specifically 90-degree elbows. These fittings are essential in plumbing and HVAC systems, enabling smooth directional changes in piping networks while maintaining flow efficiency and pressure resistance. The mold’s design and construction play a critical role in ensuring the quality, durability, and dimensional accuracy of the final product. Key Features of the PP-R 90-Degree Elbow Mold 1. Material and Durability The mold is typically made from high-grade tool steel, such as P20, H13, or stainless steel, to withstand high injection pressures and prolonged use. Hardened steel components enhance wear resistance, ensuring a long service life even under continuous production cycles. 2. Precision Engineering The mold cavity and core are CNC-machined to exact specifications, guaranteeing tight tolerances (typically within ±0.02mm) for consistent fitting dimensions. The 90-degree bend angle must be precisely maintained to ensure proper alignment when installed in piping systems. 3. Cooling System Design Efficient cooling channels are integrated into the mold to regulate temperature during the injection process. Uniform cooling minimizes warping and internal stresses in the PP-R elbow, improving product consistency and reducing cycle times. 4. Ejection Mechanism The mold incorporates ejector pins or sleeves to smoothly release the molded elbow without deformation. Proper ejection design prevents surface defects and ensures smooth demolding, even for thicker-walled fittings. 5. Surface Finish The cavity and core surfaces are polished or textured to achieve the desired finish on the PP-R elbow. A smooth interior surface reduces friction in fluid flow, while a matte exterior may be preferred for handling and aesthetics. Production Process The PP-R material is heated to a molten state and injected into the mold under high pressure. After filling the cavity, the material cools and solidifies into the elbow shape. The mold then opens, and the finished fitting is ejected. Post-processing, such as deburring or quality inspection, may follow. Applications PP-R 90-degree elbows are widely used in hot and cold water systems, industrial pipelines, and chemical transport due to their corrosion resistance, thermal stability, and leak-proof joints. The mold must produce fittings that meet international standards (e.g., ISO 15874, DIN 8077). Conclusion A well-designed PP-R 90-degree elbow mold ensures high productivity, dimensional accuracy, and long-term reliability of the fittings. Its robust construction, precision engineering, and efficient cooling system contribute to cost-effective manufacturing while maintaining the high performance expected in modern piping systems.

Bima

kitini:

-

PP ya ke monana mbote na zulu

Kukabula: PP ya kutunga tiyoNtalu ya bantu me tala: 588Ntalu:Kilumbu ya kubasika: 2025-09-16 23:46:09PP ya ke monana mbote na zuluZina ya kima : PP ya kukangama 90o ya kukangama ya tiyo ya kutula nayoMabulu:16 KazakaBima:PP.ntungulu ya mfututu: Mutindu ya cylindre ya mafutaCavité / core acier :2738 or718 sambu na dibulu mpi core .Ya ngolo ya core/cavité: HRC 40-45 degré na nima ya thérapie ya tiya ya aspirateurMashini ya kuyidika nitu:380T Taizhou Huang Yanhongjin ya plastique LD LD .1、 Kumeka na kusala bamoule ya plastique, bima kele: PPR PP PE PE ya PP mpi bima ya nkaka ya tiyo, bima ya mfunu ya bo ke sadilaka konso kilumbu, moule ya bo ke bingaka roulement de turne, moule de valve ya pl... -

40mm PPR Elbow 90 Mold ya Fit ya Kufidisa Badegre .

Kukabula: PPR ya kufwana ya kutula tiyoNtalu ya bantu me tala: 524Ntalu:Kilumbu ya kubasika: 2025-10-23 18:12:1040mm PPR Elbow 90 Mold ya Fit ya Kufidisa Badegre .Zina ya moule:40mm PPR Elbow 90 Mold ya Fit ya Kufidisa Badegre .Mabulu:2 mabuluBunene ya ntoto:20-50mmE nsongo mia mold:2738 yovo 718 muna nsongo ye nsongo .Kielo :kielo ya directntungulu ya moule: structure ya colonne ya colonne ya diagonaleYa ngolo ya core/cavité: HRC 32-45 degré na nima ya thérapie ya tiya ya aspirateurMashini ya kusala ba injection:250TTaizhou Huangyan Hong Jin mold Co., Ltd wasikidiswa muna mvu wa 2002.Tuna ye salu kia tunga e mpila yavangilwa yo vanga e nsongo mia lunga-lunga e tubi se vioka mvu 23.Beto kele na kiese ya...

Nsangu

kitini:

-

[Company News]Customer Photo

2025-12-09 21:33:14

Mambu

kitini:

Bavideo

kitini:

Ba mvutu ya kusosa kele ve!

Kubaka

kitini:

Ba mvutu ya kusosa kele ve!

Kubaka bantu na kisalu

kitini:

Ba mvutu ya kusosa kele ve!

Bima ya bo ke lomba

Ba mvutu ya kusosa kele ve!

Nki

Nki Telefone

Telefone